Search

The BUCHEN-ICS Group’s locations

The whole picture – with just a single click. Find out here where our branches are located, what services they offer and how to contact them.

The REMONDIS Group’s business locations

The addresses of all of the REMONDIS companies and branches can be found at:

High standards for more safety

Deposited material does not only reduce the storage capacity. It also impedes the material flow and can contaminate stored bulk materials. For our highly specialised silo cleaning services, we use hydraulically driven cleaning systems that are more powerful in terms of torque and impact at all operating speeds than, for example, compressed air systems. The system's whips are anti-static, spark-proof and gentle on the surface of container walls. The entire equipment meets the strict safety standards of the chemical industry and food production.

Our mobile silo cleaning systems

BinWhip® – our bin cleanout system

Our BinWhip® system consists of manually controlled telescopic arms with knuckle whips attached to them – a particularly effective method for removing deposits as the system creates such a strong rotational force. We use either UHMW whips, spark-proof bronze chains or specially produced steel chains to carry out the work depending on the type of material that needs to be removed.

BinDrill® – our bridge breaking system

Our BinDrill® system is ideal for clearing material when a silo is completely bridged or the discharge section has become clogged up. We are able to deal with the toughest of material as this system is powered by high-torque industrial hydraulic motors and we are able to choose from a variety of different drills.

Cardox® – our blockage clearing system

The Cardox® Stick system utilises a pressurised liquid CO2 capsule and small electrical circuit that is drilled into the hard material within a silo, bin, or bunker. Once the required depth is achieved the operator applies a small electric current to the Cardox® Stick. The electrical current causes the liquid CO2 to rapidly expand generating a large quantity of high-pressure gas that causes the material to heave breaking the materials so it can be removed from the silo using the bin whip or directly from the cone of the vessel.

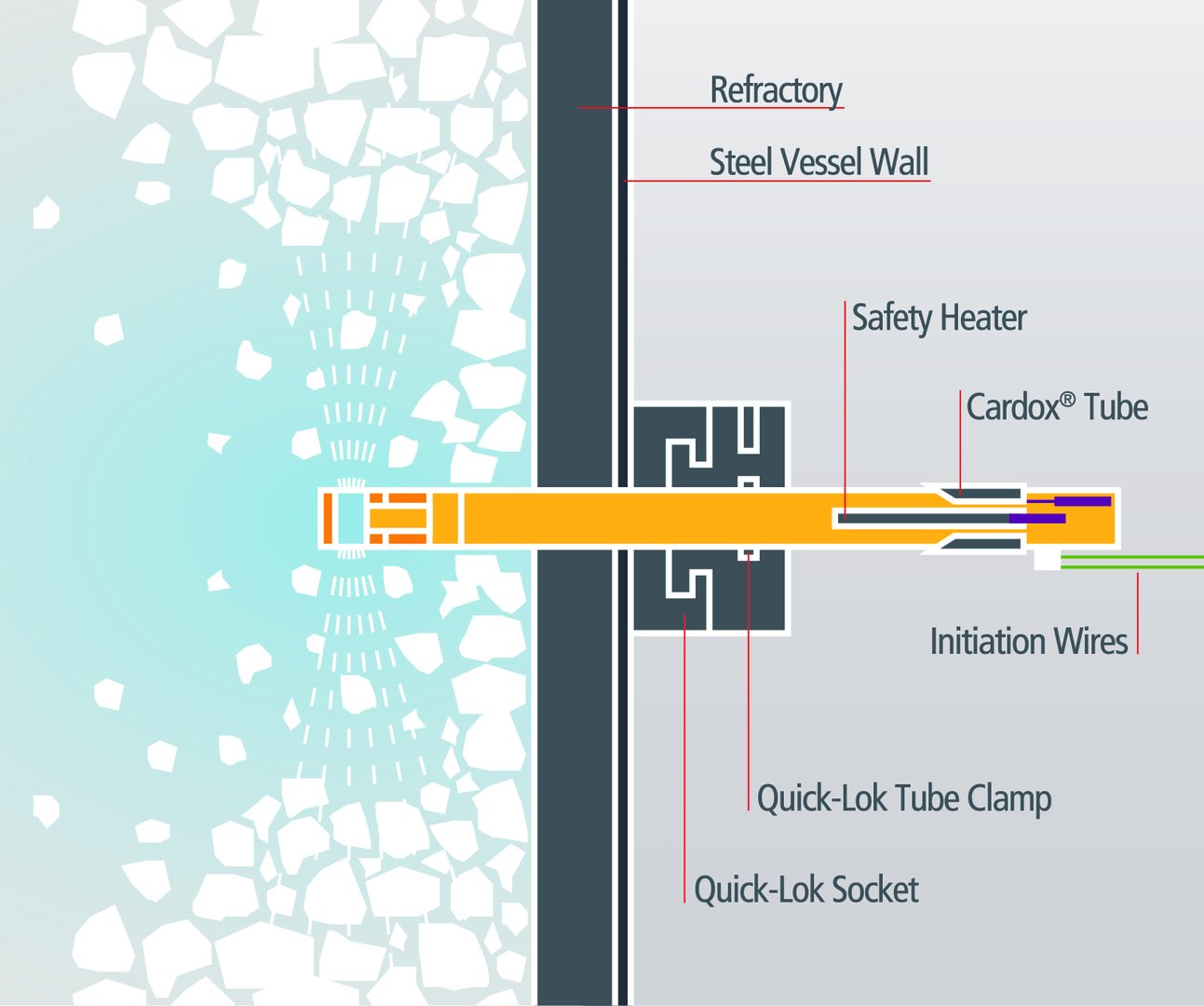

The heart of the Cardox® System is a reusable, high-strength alloy steel tube, which holds a charge of liquid carbon dioxide and a safety heater. When the heater is remotely initiated by a small electrical charge, the CO2 reaches the shear pressure of the rupture disc (up to 34,000 psi). High-pressure CO2 is instantly released through ports of the discharge head, creating a powerful force that dislodges tons of blockage in less than a second. Once fired, the Cardox® tube is rebuilt with a new Cardox® safety heater, shear disc and sealing washer and recharged with CO2 for another use.

A Cardox® cartridge cannot set off an explosion. Heat generated within the cartridge is automatically cooled by sudden expansion of carbon dioxide, and there is no flame generated.