Our silo cleaning flyer can be downloaded (PDF)

Search

The BUCHEN-ICS Group’s locations

The whole picture – with just a single click. Find out here where our branches are located, what services they offer and how to contact them.

The REMONDIS Group’s business locations

The addresses of all of the REMONDIS companies and branches can be found at:

Silo cleaning Projects

Are your silos operating at less than maximum capacity or reduced efficiency, costing you money or loss of production?

Buchen-ICS Ltd operate specialist equipment that removes the need to make manned entry in to bulk storage silos, bins, or bunkers to restore them to maximum storage capacity & operating efficiency. Without the need to entry the silo, the cleaning process is less intrusive and removes the risk of entrapment in the material, whether it be coal, fertiliser, plaster, cement, cereal, animal feed, salt, or clay.

The utilisation of the BinDrill®, BinWhip® and Cardox® technologies reduces the need to expose operatives to internal hazards of the material inside the silo or any equipment within the silo because the operation is carried out remotely from the silo top. The process of remote working also removes the potential to contaminate finished product.

With a maximum working depth of 60m, the BinDrill®, BinWhip® and Cardox® systems are essential tools in ensuring even the largest of silos are kept working efficiently at maximum capacity.

Our mobile silo cleaning systems

The cleaning equipment used for this mobile work is anti-static, spark-proof and meets the strict safety standards and hygiene regulations of both the chemical industry and the food industry. What’s more, as the systems are modular, the equipment can be installed quickly and can be adapted to the size of each individual silo. At no time during the process must the staff climb into the silo to do their cleaning work.

BinWhip® – our bin cleanout system

- Manually controlled system that gently removes deposits

- Can be used for practically all types of bulk material

- Fully restores the silo’s storage capacity

- Does not damage the silo’s walls

BinDrill® – our bridge breaking system

- Ideal for clearing material when a silo is completely bridged (up to 45m)

- Can be used for practically all types of bulk material

- Fully restores the silo’s storage capacity

- Does not damage the silo’s walls

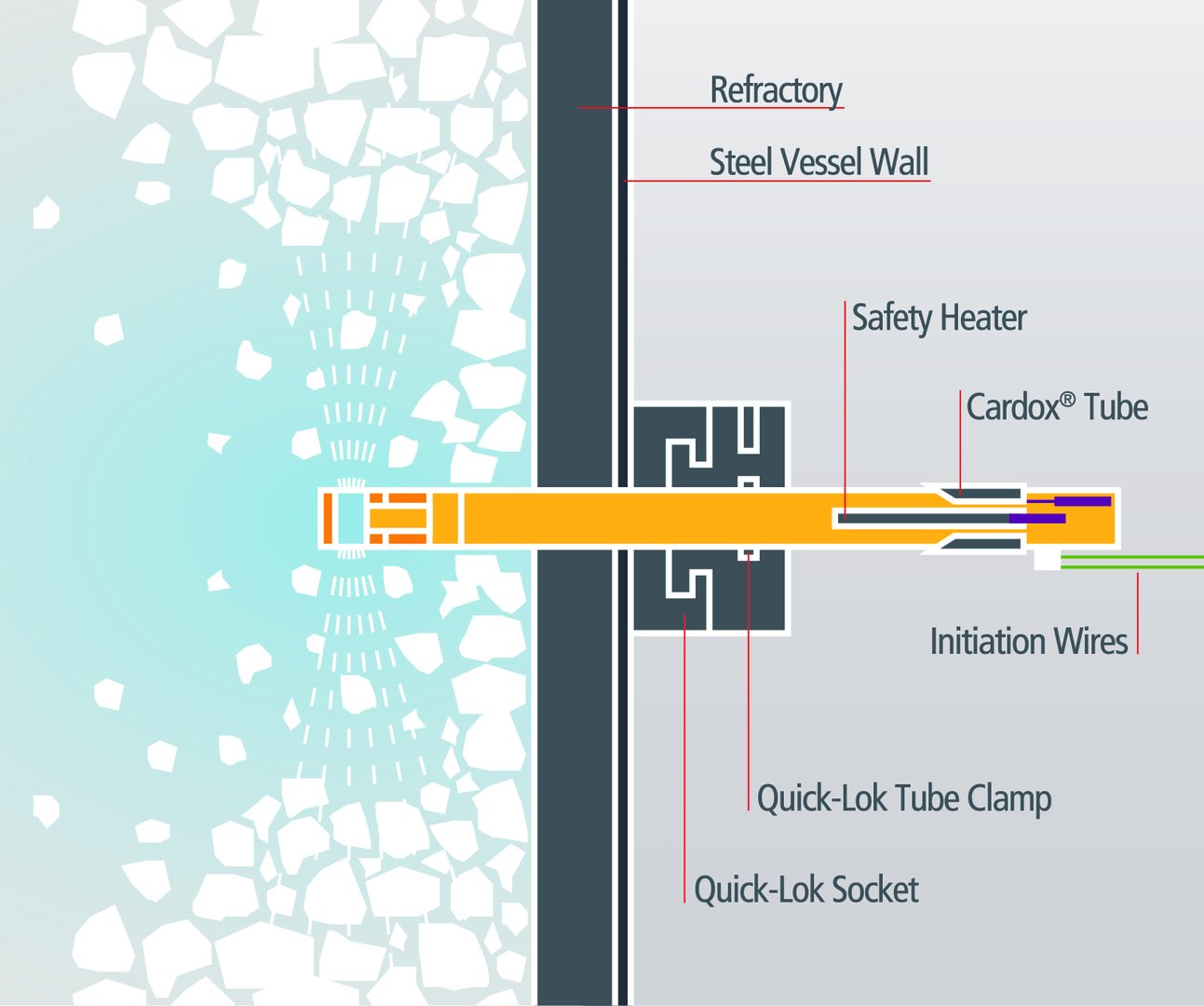

Cardox® – our blockage clearing system

- Breaks up compacted material in storage vessels by rapidly releasing liquid carbon dioxide

- Possible to install permanent Cardox® tube sockets on the outside of the silo